Advantages of PVD Coated technology

Physical vapor deposition (PVD), sometimes called physical vapor transport (PVT), describes a variety of vacuum deposition methods that can be used to produce films and coatings.

PVD is characterized by the transformation of materials from the condensed phase to the gas phase, and then back to the condensed phase.

PVD for manufacturing requires thin films for mechanical, optical, chemical or electronic functions. These include semiconductor devices such as thin-film solar panels, aluminized PET films for food packaging and balloons, and coated cutting tools for metalworking.

Advantages:

1, PVD coating is sometimes harder and more corrosion resistant than plating process applications.

2, Can be used almost any type of inorganic and some organic coating materials on equally diverse substrates and surfaces using a variety of finishes.

3, More environmentally friendly than electroplating, painting and other traditional coating process.

4. More than one technique can be used to deposit a given film.

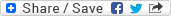

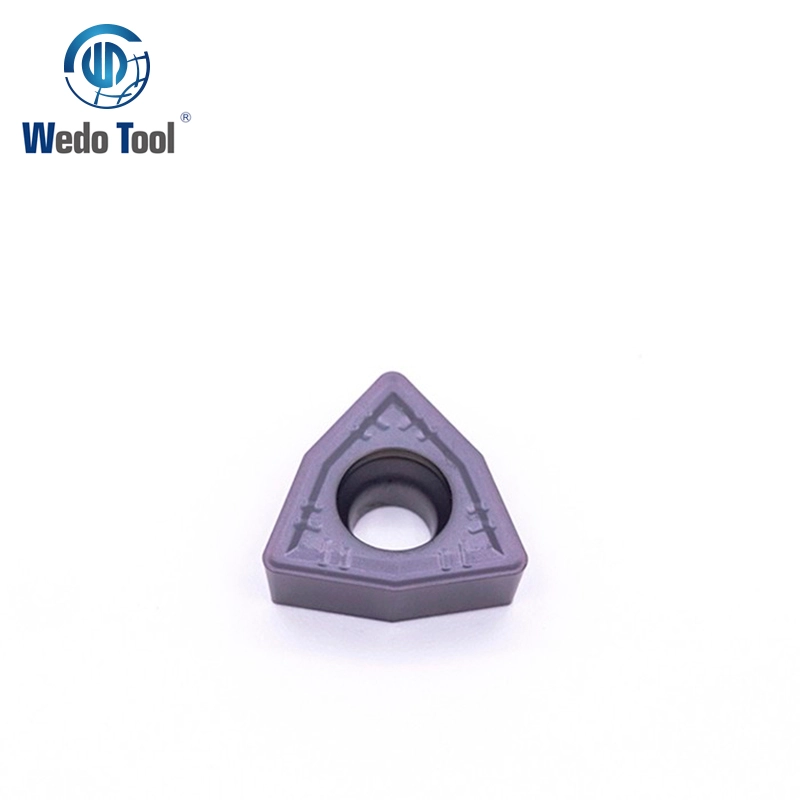

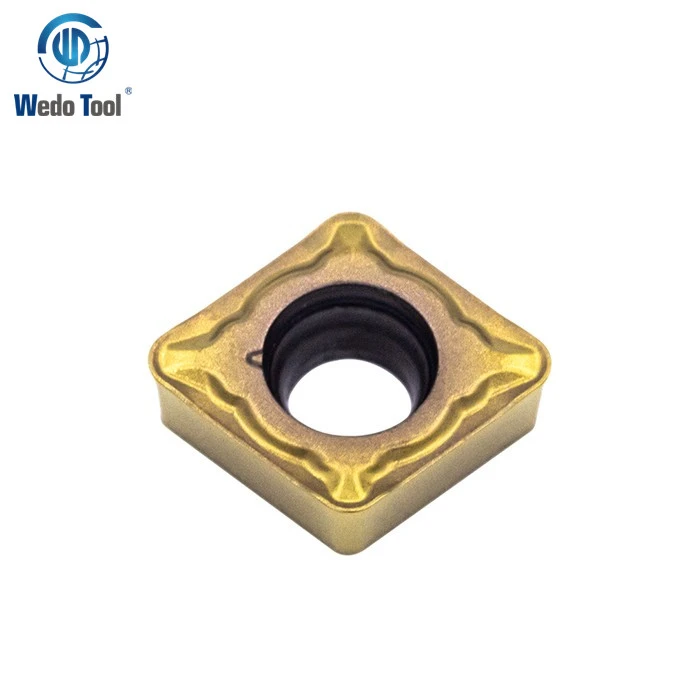

At present, Wedo cutting tools Co,Ltd can provide PVD Coated Carbide cutting tools: Turning inserts, Milling inserts, Drilling inserts.

Wedo CuttingTools Co,.Ltd is well-known as one of the leading carbide inserts suppliers in China, specialized in providing high quality products with competitive price.